| HOW TO SELECT THE RIGHT PROPELLER? |

|

|

How is your boat performing? If you are pleased with your boat’s performance, you can select another prop similar to your last one. Many boaters choose to economize when replacing a propeller, and just purchase a replacement identical to their old prop. Replacing your boat’s prop offers an opportunity to improve performance with a more appropriate pitch, two modular props with different pitches or a four-blade prop. Don’t limit your consideration to just aluminum either, but consider stainless steel, which can in some cases offer higher top end speed or improved handling, but with the tradeoff of a higher risk of lower unit damage if you strike a submerged object.

What problems are you looking to solve?

Are you looking for a quicker hole shot, so you’ll jump onto a plane more rapidly? Are you not hitting the top speed you think you should? Looking for an improvement in fuel economy? Hoping for better all-around performance? Is your current prop blowing out or ventilating excessively in turns or when you accelerate? Are you looking to improve your boat’s watersports performance for tubing, skiing or wakeboarding? Consider your goals before you talk to our associates.

The basic rule for prop selection: your engine should be running within the designed rpm range at Wide Open Throttle (WOT).

Your owner’s manual should include this spec - usually 5000-5500rpm for an outboard or 4200-5000rpm for a sterndrive - or your mechanic or dealer may know. If your engine is not able to reach its designed range it may be operating in an extremely overworked state, and mechanics indicate that running a highly loaded, lugging engine is a prime cause of premature failure. Allowing your engine to over-rev is nearly as bad, and can also cause severe damage.

What information do you need to buy a prop?

Propeller data

Essential information:

- Present prop diameter

- Present prop pitch

- Right or left hand prop rotation (clockwise is right hand)

- Number of blades

- Material

Other very useful information:

- Manufacturer’s part number

- Shaft diameter and number of splines or keyway type

Engine data

Essential information:

- Number of engines

- Rated horsepower

- Gear case size

- Rpm at WOT

- Manufacturer, model and year

Other very useful information:

- Displacement in cubic inches or centimeters

- Power trim or trim tabs

Boat data

Essential information:

- Length overall

- Hull material

Other very useful information:

- Manufacturer, model and year

- Hull shape

- Present/desired top speed

Propeller Selection Basics

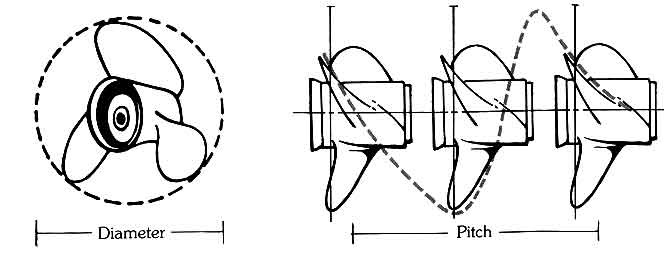

Propeller size is expressed with two numbers, diameter and pitch, with diameter always stated first. Diameter is two times the distance from the center of the hub to the tip of any blade. Smaller prop diameters generally go with smaller engines, or with fast high performing boats. Pitch is the theoretical forward distance, in inches, that a propeller travels during one revolution. There is always some “slip” between the propeller and the water (generally 10 to 15%) so the actual distance traveled is somewhat less than the theoretical value. Think of pitch as speed, or as the gear selection on a car’s transmission.

Rake is the degree that the blades slant forward or backward in relation to the hub. Rake can affect how water flows through the propeller, which can make a difference regarding boat performance. Aft rake helps to lift the boat’s bow, decreasing the hull’s wetted surface area and improving top end planing speed. Today’s aggressively raked propellers may require that you add a high performance trim tab to your shopping list. The blade tips of these new propellers may strike the older style trim tabs on your engine.

Cupping of the trailing edge of the propeller blade is common on many propellers. A downward curve of the lip of the blade (like a plane’s wing with the “flaps” down) allows a better hole shot, less slippage and ventilation, and helps the propeller get a better bite on the water. A cupped prop may allow the engine to be trimmed with the prop closer to the surface, and will also decrease rpm by 150 to 300.

Ventilation is a problem that occurs when air from the surface or exhaust gas from the engine gets drawn into the prop’s blades. The boat’s speed drops, the engine over-revs and screams, and the prop sucks air. Ventilation results from excessively tight turns, a motor that is mounted too high on the transom, or an engine that is overtrimmed. Ventilation can also occur from prop designs that are not matched to the application, poorly designed props, props with little or no cup, or props that are worn or have damaged edges or cup profiles.

Cavitation (often confused with ventilation), results from water vaporizing or “boiling” due to the extreme lack of pressure on the back of the propeller blade. Many propellers partially cavitate during normal operation, but excessive cavitation may result in “cavitation burn,” metal erosion or pitting of the prop’s blade surface. Causes of cavitation include incorrect engine height (outboards), dings or sharp corners in the leading edge, poor polishing, too much cup or crummy blade design. Cavitation can also occur from thru-hulls, sensors, or other turbulence-producing protrusions under the boat forward of the prop.

What material is the best?

Most outboards and IOs are originally sold with aluminum props, which are inexpensive and repairable. Inboards use three- and four-bladed props of bronze, or a nickel-bronze-aluminum alloy. Replacement props for IO or outboard boats are available in aluminum or stainless steel. These materials compare as follows:

Aluminum: The most common, least expensive material. Suitable for most outboard and sterndrive applications.

Stainless Steel: Performance advantage over aluminum due to stiffer, thinner blades and more advanced designs. Best choice at speeds over 50mph, or if your boat is running over oyster beds or sandbars regularly. Stainless costs more but is five times more durable than aluminum. Stainless props can be repaired, at a higher cost, to like-new condition, while repaired aluminum will suffer from metal fatigue and a loss of strength.

Choosing the right pitch

Changing the pitch will inversely effect engine rpm, so matching the right prop having the correct pitch with your engine will let you achieve the recommended WOT operating range. A two-inch increase in pitch results in a reduction of 300 to 400 rpm. A two-inch decrease in pitch results in an increase of 300 to 400 rpm. Therefore, if your engine operates below the proper rpm, consider a propeller with less pitch. If your engine revs beyond maximum recommended rpm, consider a propeller with more pitch.

Your boat may have a lot of heavy gear inside, or you may sometimes use it to tow skiers or wakeboarders, in which case the original-equipment prop may have too much pitch, causing your engine’s rpm to be on the low side. If you change configurations, sometimes running light and other times loaded with camping equipment, two props with different pitches make sense. There are two ways you can tailor your prop’s pitch to match a variety of conditions; carry two complete props or two modular props with different pitch.

Should you choose a four-blade prop?

Three or four blades work well in either sterndrive or outboard applications. Three-blade designs give you all-around performance with an advantage on top end speed. Four-blade designs work well with boats that are difficult to get on plane, underpowered or used in watersports where top-end speed is not critical.

Four blades in many cases will drop your rpm by 50 to 150rpm with identical pitch. Three-blade props are generally best for recreational boats with three-, four- and six-cylinder outboards and sterndrives, giving good hole shot and top-end performance.

The blades on three-blade props fill up about 50 to 55% of the available area inside the circle formed by the prop’s diameter (referred to as the Diameter Area Ratio). Adding a fourth blade increases the DAR to between 60 and 65%, so you can expect more thrust to keep your boat planing at lower rpm, a potential boost in fuel economy, but also reduction in WOT rpm of between 50 and 100.

Products

OMC, 14,2" x 23", 90-300 HP

SOL2511-142-23

TOHATSU, 7 1/4" x 6", 2,5-3,3 HP

SOL0001-073-06P

JOHNSON/EVINRUDE, 12,5" x 14", 40-75 HP

SOL2311-125-14

PROPELLER - SUZUKI, 15" x 15"

SOL4511-150-15

PROPELLER - SUZUKI, 11.6" x 12"

SOL4311-116-12

|